Process Flow Chart Of Gold Iron Ore Benification

sbm/sbm process flow chart of gold iron ore

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Iron Ore Beneficiation Multotec

Iron Ore beneficiation solutions from Multotec are designed so that each stage of the mineral beneficiation process, from ROM stockpiles to processed minerals and tailings,

Mineral Processing Flowsheets

2016年3月8日The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating

Beneficiation of Iron Ore Mineral ProcessingMetallurgy

2016年5月24日The iron ore beneficiation flowsheet presented is typical of the large tonnage magnetic taconite operations. Multi-parallel circuits are necessary, but for purposes of illustration and description a single circuit

Beneficiation of Iron Ores IspatGuru

2014年4月3日A typical flow sheet for iron ore beneficiation plant is shown in Fig 1. The process is used for iron ore fines with size range of 0.2mm to 6 mm. The cyclone type separator utilizes centrifugal as well

Iron Ore Beneficiation Mineral Processing

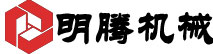

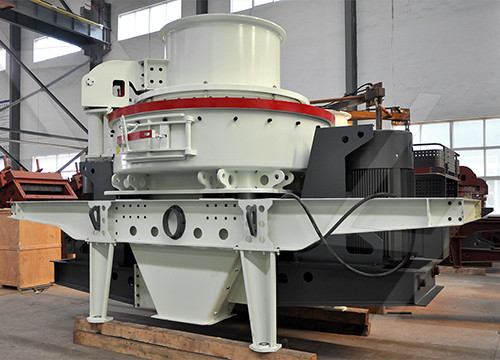

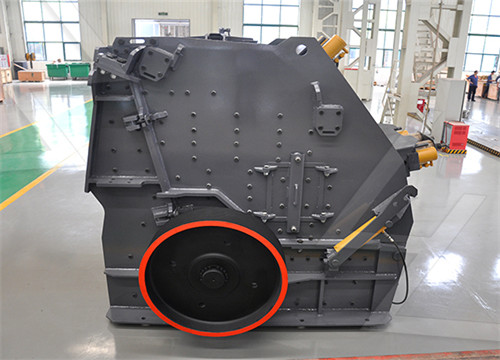

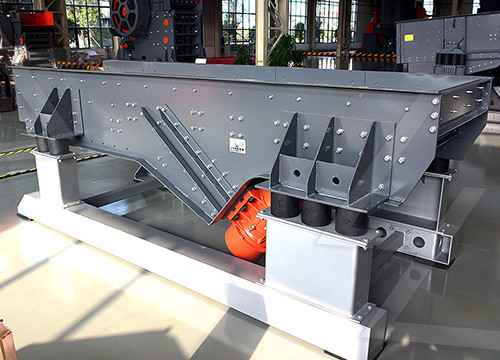

Iron Ore Processing Plant The iron ore beneficiation process mainly includes crushing, screening, grinding (ball mill), classification (classifier), separation (gravity separation,

Iron ore beneficiation technology and process

2020年12月17日The common process flow in actual production is: the raw ore is fed into the shaft furnace for roasting and magnetization, and after magnetization, it is fed into the

Flow chart for iron ore beneficiation YouTube

Now chatting: leawaysschool/solution.htmlContact Us: leawaysschoolleaching of iron ore process flowchart ? SCMMining> M...

Beneficiation Wikipedia

In the mining industry or extractive metallurgy, beneficiation is any process that improves (benefits) the economic value of the ore by removing the gangue minerals, which results in a higher grade product ( ore concentrate) and a waste stream ( tailings ).

sbm/sbm process flow chart of gold iron ore benification.md at

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Iron Ore Beneficiation Multotec

Overview of a typical Iron Ore Process flow sheet: Primary stages of iron ore beneficiation, essentially, result in three iron ore product types, namely Coarse, Medium and Fine. Coarse Product From the ROM stockpile ore is crushed and screened using gyratory crushers, grizzly screens and cone crushers before being sized through a sizing

Beneficiation Plants and Pelletizing Plants for Utilizing Low

1.3 Structure of iron ore supply The suppliers of iron ore have undergone strategic restructuring since 2000. Three majors, namely, Vale (Brazil), Rio Tinto, and BHP Billiton (the latter two companies having two head offices, in the UK and Australia), now account for approximately 65% of the iron ore traded across the world.

(PDF) Iron Ore Pelletizing Process: An Overview

2018年7月11日Iron ore fines generated from the beneficiation process cannot be used directly in blast furnaces for steel making. So these fines are converted into sized spherical balls, known as iron ore

Technical Resource Document: Extraction and

Table 1-3. Ore Treated to Product Ratios and Material Handled to Product Ratios for U.S. Surface Iron Ore Mines, in Thousand Long Tons, 1988 .. 1-13 Table 1-4. Beneficiation Methods Commonly Associated With Iron Ores and the Percentage of Ore Treated by Each Method, 1990 .. 1-15 Table 1-5.

Iron ore beneficiation technology and process

2020年12月17日The following summarizes some common iron ore beneficiation processes according to the different properties of the ore: Strong magnetic iron ore 1.Single magnetite. The composition of iron ore of a single magnetite type is simple, and the proportion of iron minerals is very large. Gangue minerals are mostly quartz and silicate

Iron Ore Beneficiation Mineral Processing

Iron Ore Processing Plant The iron ore beneficiation process mainly includes crushing, screening, grinding (ball mill), classification (classifier), separation (gravity separation, flotation, magnetic separation), and mineral dehydration

Iron Ore Processing Flow Sheet multotec

We use cookies to improve your experience on our website. By using our site you agree to Cookies Policy

Iron Ore Beneficiation Process Metallurgist

2017年4月27日The general processes to which low grade iron ores are amenable are as follows: Thermal (a) Drying; removes hydroscopic or atmospheric moisture. (b) Calcining; removes carbon dioxide from iron

Flow chart for iron ore beneficiation YouTube

Now chatting: leawaysschool/solution.htmlContact Us: leawaysschoolleaching of iron ore process flowchart ? SCMMining> M...

Ore Beneficiation an overview ScienceDirect Topics

Conventional beneficiation processes such as flotation, electrostatic and magnetic separation, gravity methods and flocculation–dispersion using chemical reagents to treat the finer iron ore resources often prove to be inefficient, energy-intensive, costly, and environmentally-toxic.

1.1 PHASES OF A MINING PROJECT ELAW

one percent. The gold content of a good grade gold ore may be only a few one-hundredths of a percent. Therefore, the next step in mining is grinding (or milling) the ore and separating the relatively small quantities of metal from the non-metallic material of the ore in a process called ‘beneficiation.’ Milling is one of the most costly

sbmchina/sbm flowchart crushing crusher.md at main github

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Beneficiation Wikipedia

In the mining industry or extractive metallurgy, beneficiation is any process that improves (benefits) the economic value of the ore by removing the gangue minerals, which results in a higher grade product ( ore concentrate) and a waste stream ( tailings ).

Ore Beneficiation an overview ScienceDirect Topics

Conventional beneficiation processes such as flotation, electrostatic and magnetic separation, gravity methods and flocculation–dispersion using chemical reagents to treat the finer iron ore resources often prove to be inefficient, energy-intensive, costly, and environmentally-toxic.

sbm/sbm process flow chart of gold iron ore benification.md at

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Beneficiation Plants and Pelletizing Plants for Utilizing Low

1.3 Structure of iron ore supply The suppliers of iron ore have undergone strategic restructuring since 2000. Three majors, namely, Vale (Brazil), Rio Tinto, and BHP Billiton (the latter two companies having two head offices, in the UK and Australia), now account for approximately 65% of the iron ore traded across the world.

(PDF) Iron Ore Pelletizing Process: An Overview

2018年7月11日Iron ore fines generated from the beneficiation process cannot be used directly in blast furnaces for steel making. So these fines are converted into sized spherical balls, known as iron ore

Technical Resource Document: Extraction and

Table 1-3. Ore Treated to Product Ratios and Material Handled to Product Ratios for U.S. Surface Iron Ore Mines, in Thousand Long Tons, 1988 .. 1-13 Table 1-4. Beneficiation Methods Commonly Associated With Iron Ores and the Percentage of Ore Treated by Each Method, 1990 .. 1-15 Table 1-5.

The six main steps of iron ore processing Multotec

Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

Iron ore beneficiation technology and process

2020年12月17日The common process flow in actual production is: the raw ore is fed into the shaft furnace for roasting and magnetization, and after magnetization, it is fed into the magnetic separator for magnetic separation. (2) Flotation, re-election, strong magnetic separation or their combined process

Mineral Processing Equipment Multotec

Driven by a global team of process engineers and metallurgical specialists, Multotec designs, builds, manufactures, installs and maintains equipment throughout the entire value chain of mineral processing plants across all

Flow chart for iron ore beneficiation YouTube

Now chatting: leawaysschool/solution.htmlContact Us: leawaysschoolleaching of iron ore process flowchart ? SCMMining> M...

Iron Ore Processing Flowsheet Grinder Process

The iron ore processing flowsheet is consists of two processes:Dry Processing and Wet Processing. The primary beneficiation plant consists of only a jaw crusher and from there the material is transferred to the secondary plant via conveyor belt method. The main objective of the primary beneficiation plant is the crushing of the ROM from the

1.1 PHASES OF A MINING PROJECT ELAW

one percent. The gold content of a good grade gold ore may be only a few one-hundredths of a percent. Therefore, the next step in mining is grinding (or milling) the ore and separating the relatively small quantities of metal from the non-metallic material of the ore in a process called ‘beneficiation.’ Milling is one of the most costly

Advances in Low Grade Iron Ore Beneficiation MECON

iron ore is expected to rise by more than 200 million tonne per year to meet the internal demandexport. This additional requirement of iron ore will need beneficiation of low grade ore/fines to get the major portion of increased demand. This stone deals in brief to use of available methodologies for beneficiation of iron ore in Indian context.