Internal Parts Of Hummer Mill Crushers

Hammermill Crushers McLanahan

The Standard and Non-Clog Industrial Hammermills are designed to reduce the material to a nominal 3" to 5" (75mm to 25mm) output. These are primary stage crushers, commonly followed with Centerfeed Mills or other types of secondary stage crushers. The

Hammer Mill CrusherGrinder Mineral ProcessingMetallurgy

ScopeAdvantagesPurposeExampleSignificanceMechanismRatingsEffectsTechnologyOperationConstructionUse

What is intended to take place inside a hammermill is the uniform, efficient reduction of the material introduced into the grinding chamber. This particle reduction occurs as a result of the impact between a rapidly moving hammer and a relatively slow moving particle. If sufficient energy is transferred during the collision, the particle breaks and...

Industral Crushing Hammer Mill

2016年2月24日Key Features. • Designed with the heaviest, most wear-resistant components of any equipment of its kind, the RC Series

Hammer Mill Replacement Parts Allegheny Manufacturing, LLC

2019年7月16日Allegheny Manufacturing carries a large inventory of replacement wear parts for bulk handling equipment, hammer mills, and impact crushers. We can provide

Replacement Wear Parts Schutte Hammermill

2016年2月15日We maintain a large inventory of replacement wear parts for all current product offerings, as well as all Schutte Pulverizer and Buffalo Hammermill models.

Full Circle Hammer Mill Air Swept Mill Stedman Machine

Stedman’s full circle hammer mill boasts the features you require to deliver the finer grind you want: Higher throughput due to the greater screen area. Air swept design allows the

Internal Parts Of Hammer Mill Crusher Mills, Cone Crusher, Jaw

parts of an hammer mill Grinding Mill China ? parts of an hammer mill ? grinder machine price in pakistan; Contact Us. Tel: 86-21-; Office Add: Pudong New

internal parts of hummer mill crushers

internal parts of hummer mill crushers. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size

internal parts of hummer mill crushers

internal part impact crusher. internal parts of hummer mill crushers YouTube 10 Feb 2014 Internal parts of hammer mill crushers 25 components of an Impact crusher like

Industrial Hammer Mill Crusher Stedman Machine

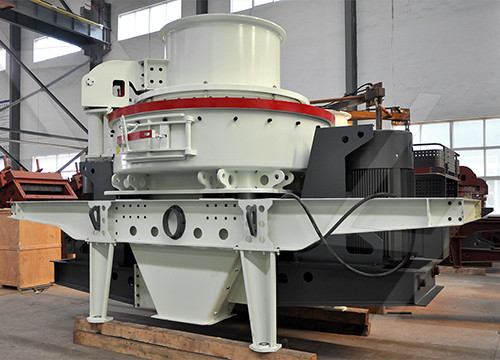

A hammer mill is a rock crusher that employs a rain of hammer blows to shatter and disintegrate a variety of materials. Hammer mills produce a finished product size that is dependent upon the following criteria: Openings in perforated screens or grate bars Number, size, and type of hammers Grinding plate setting Rotor speed Ask a Question

Industral Crushing Hammer Mill

2016年2月24日• Internal, replaceable breaker wear plate made from 1” thick AR-500 steel. Replaceable side liner plates made from ⅜” abrasion resistant steel. • Heavy duty abrasion-resistant bar grate available in

Lump Breakers and Crushers Archives Schutte Hammermill

Lump breakers are ideal most common de-agglomeration applications, and where flowability is the goal. Industrial hammer mills and jaw crushers are the size reduction equipment of choice for processing large, blocky and/or abrasive materials. Schutte-Buffalo offers an extensive line of lump breakers, industrial hammer mills, and jaw crushers. All models

Reversible Hammer Mill Crusher Williams Patent

Williams Patent Crusher has designed a reversible hammer mill that is characterized by the ability to reverse the direction of the rotor that supports the hammers. This ability brings fresh grinding edges into action,

Hammer Mill Machine Hammer Crusher Large

The structure and working principle of the hammer crusher. Structure: The hammer mill is currently the most widely used type of mill, with a relatively high volume of electrical products and good versatility.Its structure

Hammermill Impactors Eagle Crusher

Provides highly efficient internal screening capability via the adjustable heavy-duty grate bars. Maintains precise positioning and smooth performance of the bearing housing at all times with its recessed pillow-block mounting. Eliminates rotor shifting during operation via special steel locking nut and locking washer on rotor shaft.

Development and Performance Evaluation of Improved

2018年7月22日Oluwole et.al (2019) tested a small milling machine powered by a small petrol engine, where the speed of the grinder can be controlled with the stability of the drive train (weight of the rotating...

Hammer Mill Parts ProductsSuppliers GlobalSpec

Description: and rollers, sprockets, idlers, hammers, wobblers, excavators, shafts, gear teeth, steel mill roll necks and ends, and all carbon steel parts requiring build-up prior to hardsurfacing. Alloy Type: Hardfacing / Repair Alloy Tensile Strength (UTS): 105000 psi Supplier Catalog Go To Website View Specs

CPM Hammermill Hammers

Ordering Information We have every part you need to keep your hammermill running smoothly. Contact us today for replacement or backup parts, and be sure you're getting exactly the piece you need. To order parts from our parts specialists, call 1-800-366-2563 or fill out the form below. Contact Parts Department

internal parts of hummer mill crushers

all internal parts of crusher. coal crusher internal parts addoor.biz. internal part of hummer mill crusher solidarite-atakora. MECHANICAL SPARE PARTS FOR CRUSHERS AND, The hammer mills operate according to the principle of collision: the inert materials, with the bars (or balls) that crush it against the internal surface of the mill .

Hammer Mill Crusher Super Hammer Mills From Shuliy, 2022

Cyclone diameter. 1m. Capacity. 0.6-0.8t/h. You can now ask our project managers for technical details. contact now. The function of this hammer mill crusher is mainly to process charcoal blocks, straw, etc. into sawdust. This hammer crusher is often used in production lines, often together with the large chipper or comprehensive shredder.

Impact Crusher Vs. Hammer Crusher: 8 Key Differences

2023年2月15日Hammer crusher: The crushing ratio is large (generally 10-25, even to 50). The output size is 25 mm or less. The product contains more needles, flakes, and powders. 7. Different in wear of wear parts Whether for the impact crusher or hammer crusher, the plate hammer and hammer head are the main wear parts.

Limestone Mills Limestone CrushersPulverizers

Williams Direct Injection Roller Mills are used as limestone grinding machines and can grind to very exact particle sizes that are required for efficient SO2 removal. These limestone mills are designed to operate at

What is the difference between hammer crusher and impact crusher?

2022年2月19日Hammer Mill VS Impact Crusher 1. Differences in structure. Hammer crusher: It is mainly composed of body, transmission device, rotor and so on. The transmission device includes a V-belt, a winding motor and a pulley. The rotor with hammer head is the part of the hammer crusher, and its surface has a layer of material to avoid

Lump Breakers and Crushers Archives Schutte Hammermill

Lump breakers are ideal most common de-agglomeration applications, and where flowability is the goal. Industrial hammer mills and jaw crushers are the size reduction equipment of choice for processing large, blocky and/or abrasive materials. Schutte-Buffalo offers an extensive line of lump breakers, industrial hammer mills, and jaw crushers. All models

Reversible Hammer Mill Crusher Williams Patent

The following are the most popular materials for the application of our reversible hammer mills: Clay and other biological and earthly materials Coal —for reduction into a fuel source Limestone —specifically

Hammer Mill Machine Hammer Crusher Large

The structure and working principle of the hammer crusher. Structure: The hammer mill is currently the most widely used type of mill, with a relatively high volume of electrical products and good versatility.Its structure

Limestone Mills Limestone CrushersPulverizers

Williams Direct Injection Roller Mills are used as limestone grinding machines and can grind to very exact particle sizes that are required for efficient SO2 removal. These limestone mills are designed to operate at

Hammermill Impactors Eagle Crusher

Provides highly efficient internal screening capability via the adjustable heavy-duty grate bars. Maintains precise positioning and smooth performance of the bearing housing at all times with its recessed pillow-block mounting. Eliminates rotor shifting during operation via special steel locking nut and locking washer on rotor shaft.

Development and Performance Evaluation of Improved

2018年7月22日Oluwole et.al (2019) tested a small milling machine powered by a small petrol engine, where the speed of the grinder can be controlled with the stability of the drive train (weight of the rotating...

Hammer Crusher Hammer Mill Crushers for Sale

Hammer stone crusher is a kind of equipment that crushes materials in the form of impact. Crushing the size of 600-1800 mm material to 25m or less. Hammermill machine can not only be used in stone crusher plant, sand

Scrap Metal Hammer Mill Build, Parts, Design For Shredding YouTube

2020年1月21日Our largest 34"x24" scrap metal hammer mill for crushing, shredding and liberation of valuable metals. In this video Jason walks through the hammer mill ope...

Hammer Mill Crusher Super Hammer Mills From Shuliy, 2022

Cyclone diameter. 1m. Capacity. 0.6-0.8t/h. You can now ask our project managers for technical details. contact now. The function of this hammer mill crusher is mainly to process charcoal blocks, straw, etc. into sawdust. This hammer crusher is often used in production lines, often together with the large chipper or comprehensive shredder.

internal parts of hummer mill crushers

all internal parts of crusher. coal crusher internal parts addoor.biz. internal part of hummer mill crusher solidarite-atakora. MECHANICAL SPARE PARTS FOR CRUSHERS AND, The hammer mills operate according to the principle of collision: the inert materials, with the bars (or balls) that crush it against the internal surface of the mill .

Impact Crusher Vs. Hammer Crusher: 8 Key Differences

2023年2月15日Hammer crusher: The crushing ratio is large (generally 10-25, even to 50). The output size is 25 mm or less. The product contains more needles, flakes, and powders. 7. Different in wear of wear parts

MBMMLLC: Diesel powered rock crusher hammer mill

This is a demonstration for a client running a 12"x9" hammer mill dry with a 1 mm bar gap spacing. At the end of the video we show the results of the test u...

Jeffrey Rader Type AB Size Reduction Equipment Crushers

Backed by more than 90 years of application experience, each model in our complete line of Jeffrey Rader hammermills is constructed with heavy plate steel, equipped with heavy-duty components that ensure long service life, and engineered to deliver proven performance benefits. hammer mill. size reduction. stone shredder. waste . bar screen.

What is the difference between hammer crusher and impact crusher?

2022年2月19日Hammer Mill VS Impact Crusher 1. Differences in structure. Hammer crusher: It is mainly composed of body, transmission device, rotor and so on. The transmission device includes a V-belt, a winding motor and a pulley. The rotor with hammer head is the part of the hammer crusher, and its surface has a layer of material to avoid